Classic Polyester paint

Polyester paints are the most widespread, common and the most economical laminate coatings. They are suitable for both exterior and interior surfaces. With a nominal coating thickness of > 20μm they have very good resistance to external environmental conditions.

Durable Plastisol paint

The Plastisol coating is extremely resistant to outdoor weather conditions. It belongs to the category of “self-healing” coatings in mechanical damages. With a nominal coating thickness of 200μm, it is suitable for external applications where the requirements for strength are high.

High demand PVDF paint

PVDF paint is suitable for buildings with architectural applications where texture and color retention are important. The nominal thickness of the coating is 50μm and it is classified in category s1, in terms of its reaction to fire.

Coating color options

An extremely large number of coating color options are available. Please ask us about available colors (RAL1014 to RAL 9010).

| Nominal thickness |

Panel weight * |

Thermal Coefficient ** |

Fire Resistance Index *** |

| [mm] |

[kg/m2] |

[W/m2.K] |

|

| 50 |

15,2 |

0,63 |

REI 45 |

| 60 |

15,9 |

0,53 |

REI 120 |

| 80 |

18,3 |

0,40 |

REI 120 |

| 100 |

19,9 |

0,32 |

REI 120 |

| 120 |

22,2 |

0,27 |

– |

| 150 |

25,3 |

0,21 |

REI 240

|

* Panel weight (kg/m2) was calculated considering a core density of 100kg/m3, and a nominal thickness of the laminates of 0.50mm / 0.50mm.

** The thermal permeability coefficient was calculated taking into account the core density of 100kg/m3, the thermal conductivity coefficient of the core of 0.033 W/mK and the nominal thickness of the sheets 0.50mm / 0.50mm.

*** The fire resistance index results from tests carried out in notified laboratories, according to EN 13501-2 standard.

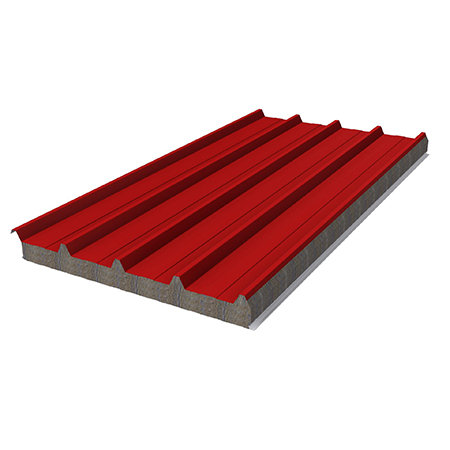

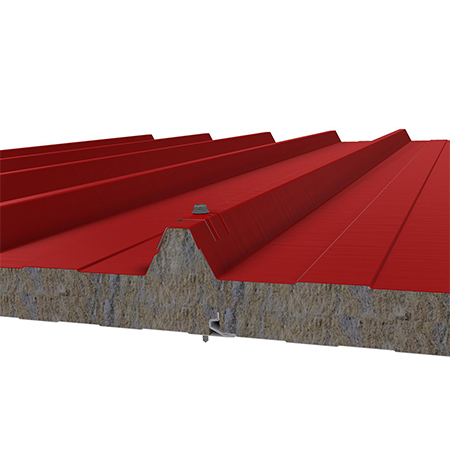

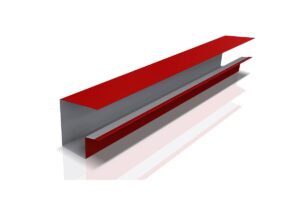

Rockwool ceiling panels are fixed to the load-bearing body by the standard method of visible anchoring.

They are designed to cover roofs with a slope of no less than 10%. On roofs with a greater slope it is recommended to install more than one panel in the direction of the slope. In this case the panels must have an overlap configuration. The cross overlap can be right or left depending on project specifications. The length of the coating varies from 50mm to 300mm. The panels are usually supplied without cross-lamination and the cut-out (removal of part of the inner lamina and core) is done at the project site.

The special joint design of the panels in combination with the use of sealants minimizes the joints from panel to panel and therefore achieves:

- Reduction of thermal bridges to a minimum

- Increase in fire resistance

- Limitation of air and moisture penetration

- Minimize setup time

- Limited use of additional accessories

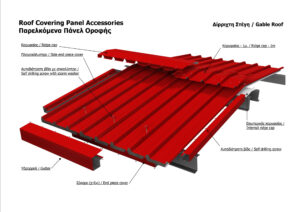

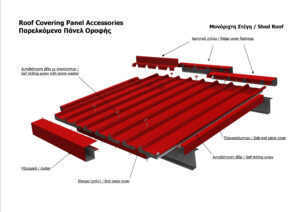

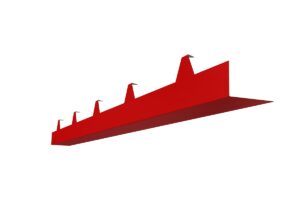

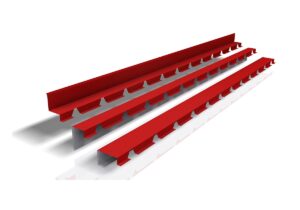

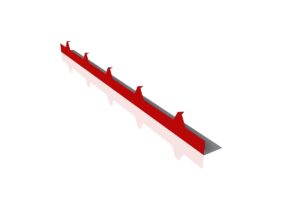

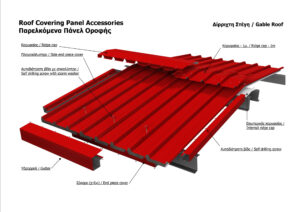

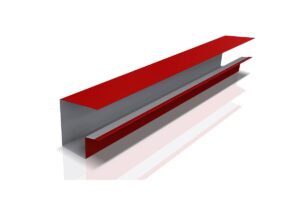

Gable roof accessories

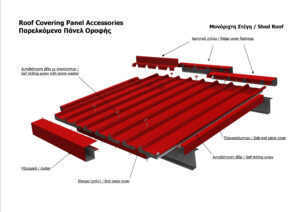

Single pitched roof accessories

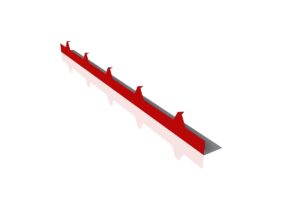

Metal profile trapezoid 42/250

Translucent trapezoidal leaves

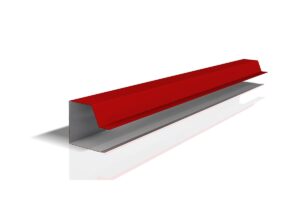

Exterior roof top

Interior top ceiling

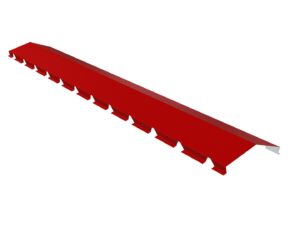

Roof side cover

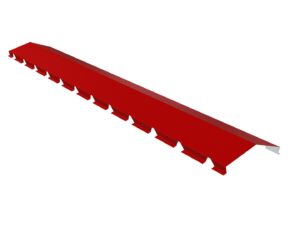

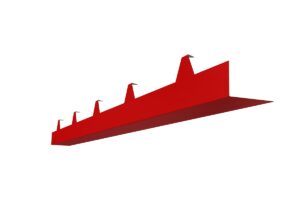

Roof comb

Top (negative scallop) ceiling

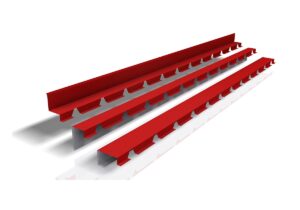

Roof drain

Your special pieces

Download our catalogues

Πανελ Οροφής Πολυουρεθάνης Φύλλο-Δεδομένων-Προϊόντος

Product-Data-Sheet

Πανελ Οροφής Πολυουρεθάνης Οδηγίες-Προϊόντος-Roof

Product Instructions