Metal type 80/293

The standardized cold-rolled thin-walled cross-sections as Metallotype 80/293, are produced based on the company’s high quality criteria, covering a wide range of applications. They are produced in desired lengths up to 14m depending on the requirements of the project.

Profiles 80/293, due to their design, can carry large loads and be used as independent structural elements in light constructions, e.g. for lofts. By using it as a metal formwork for the injection of concrete, economy is achieved in construction as shorter erection times are required and the use of formwork is avoided.

Obviously, the number of applications of these cross-sections is unlimited, provided that the static study of the structure has been prepared.

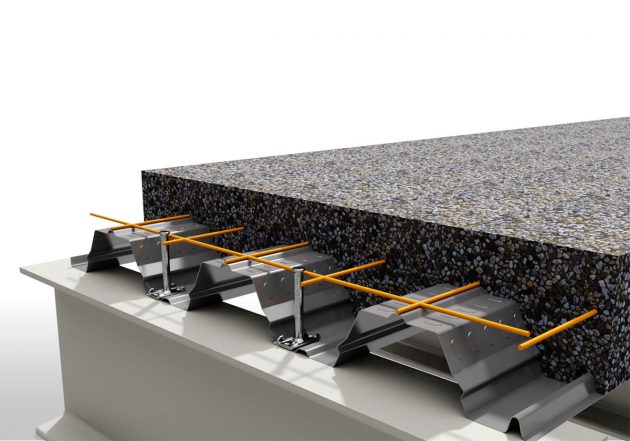

Composite plate 80/293

The composite slab consists of a standard 80/293 cross-section steel sheet with a panel and cast-in-place concrete. The standardized steel sheets initially act as a formwork and after the concrete has hardened as a composite plate. Usually the quality of concrete used is C 20/25.

When the static system is a continuous beam of many spans, to absorb the negative moments of the supports and protect against cracking, a light reinforcement is usually placed. The reinforcement can be steel mesh, quality B500C, from Φ8/20 to Φ10/15 depending on the thickness of the plate from 0.14m to 0.20m.