Characteristic Materials

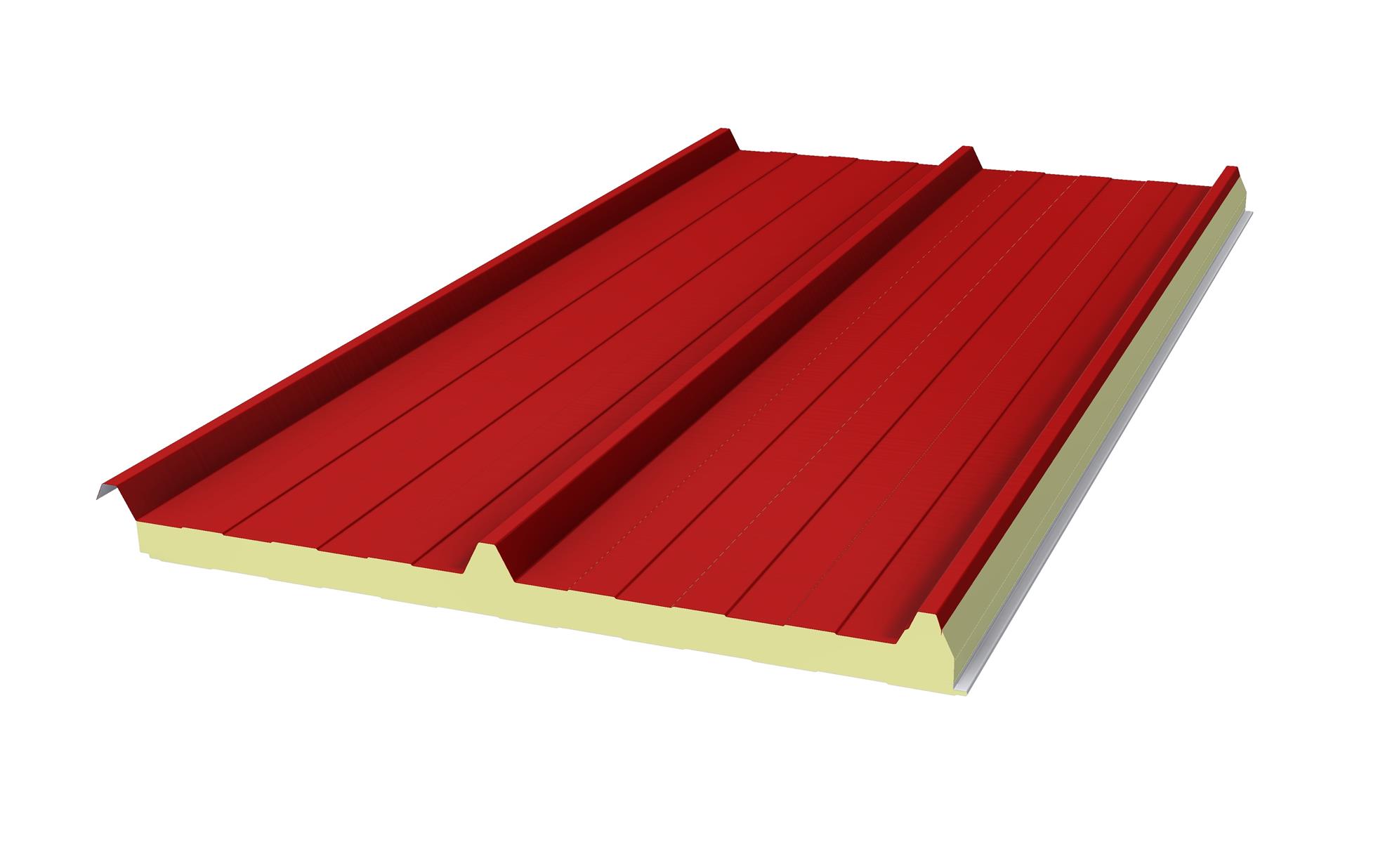

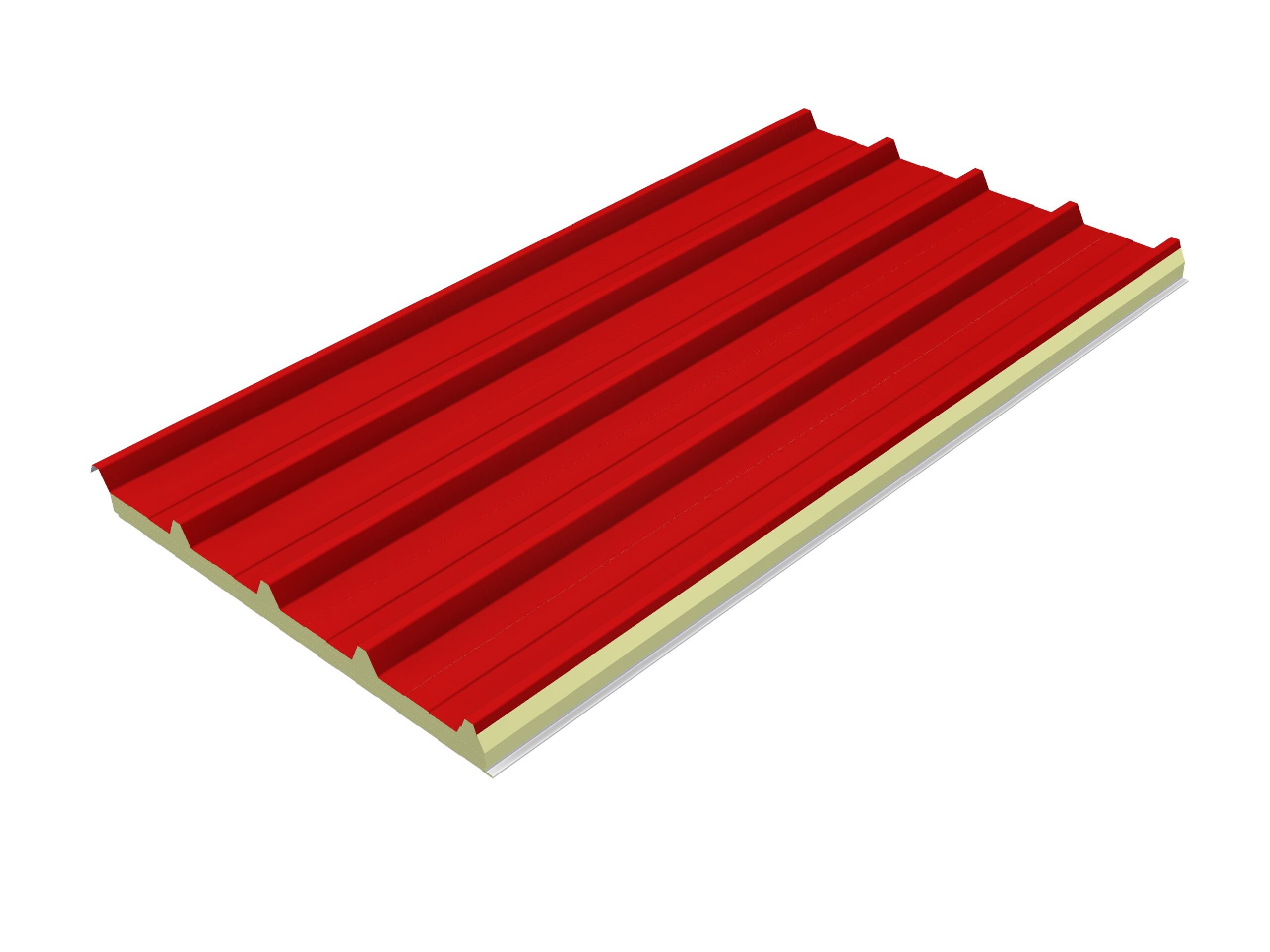

Insulating polyurethane core PUR/PIR

The 40 kg/m3 high density PUR polyurethane foam insulating core has excellent resistance to heat transmission. It is proven to be the best thermal insulation material in the field of construction.

It does not contain dangerous harmful substances, it is odorless and safe for health and the environment. Does not contain CFC & HCFC, substances that damage the ozone. It is recyclable and can be used to produce secondary use products

In addition, PIR polyurethane foam is not flammable, it is suitable for buildings with fire resistance requirements of their structural elements. The PIR polyurethane foam panel is classified in category B-s1-d0, according to the EN 13501-1 standard, i.e. it does not transmit fire, is difficult to ignite, has minimal smoke production and does not produce flammable or non-flammable particles.

Essential features:

- Density 40 ± 2 kg/m3 (high index)

- Thermal conductivity, λ 0.023 W/mK

- 95% closed cell structure

- Reaction to fire, self-extinguishing, class B s1 d0

Sheets

Pre-painted and galvanized steel sheets of 0.50 mm thickness are usually used. It is possible to choose a sheet of different materials and thicknesses.

- Pre-painted and galvanized steel or with aluzinc protection, according to EN 10346 & EN 10143, from 0.35 mm to 1.0 mm, with Polyester, Plastisol, PVDF coatings.

- Aluminum, unpainted with aluzinc protection or pre-painted with AluZinc protection, according to EN 508-2, with a thickness from 0.35 mm to 1.0 mm.

- Stainless steel, AISI 304 2B or AISI 316 L, from 0.35 mm to 1.0 mm, without color coating, mat or gloss.

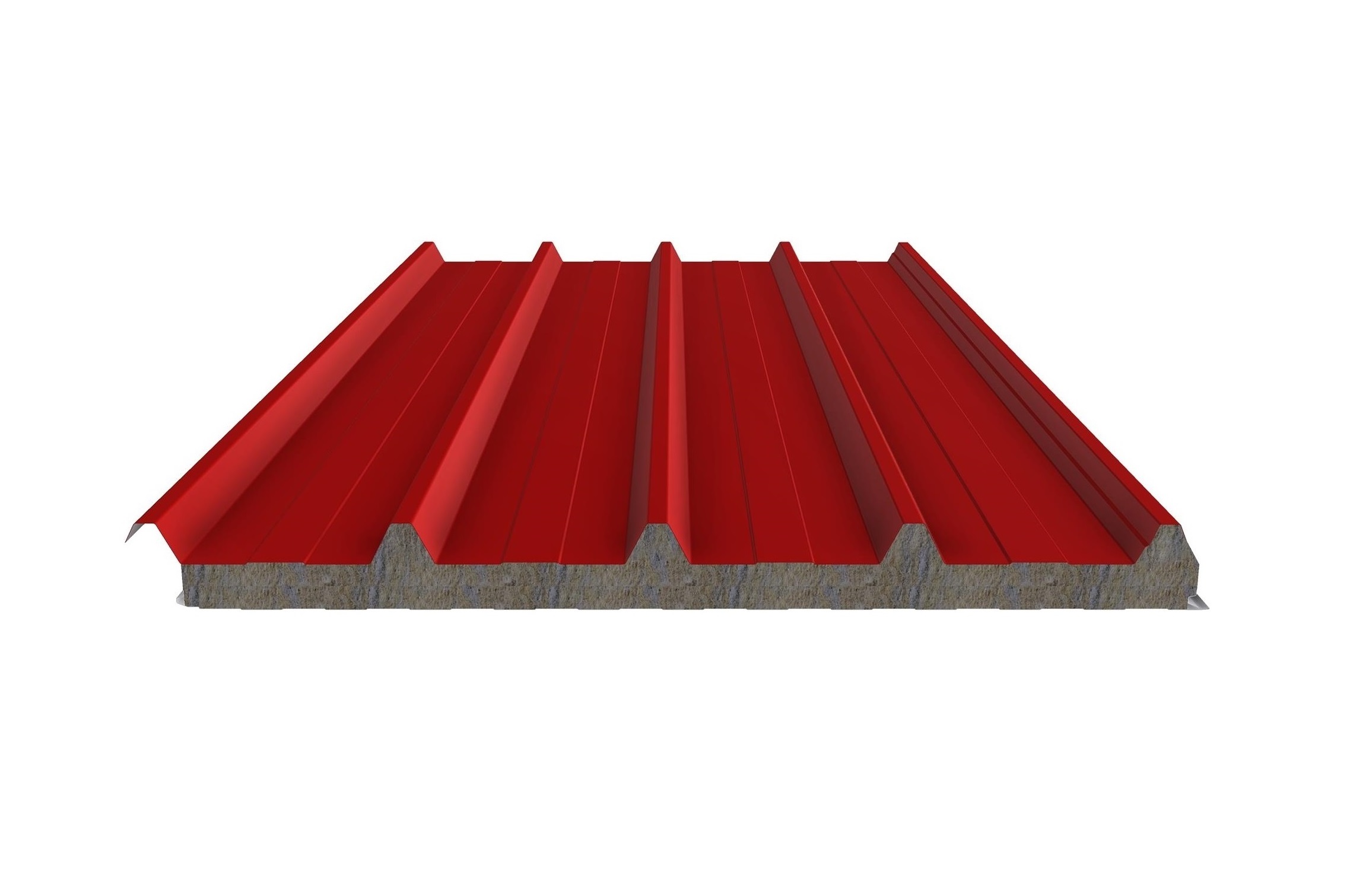

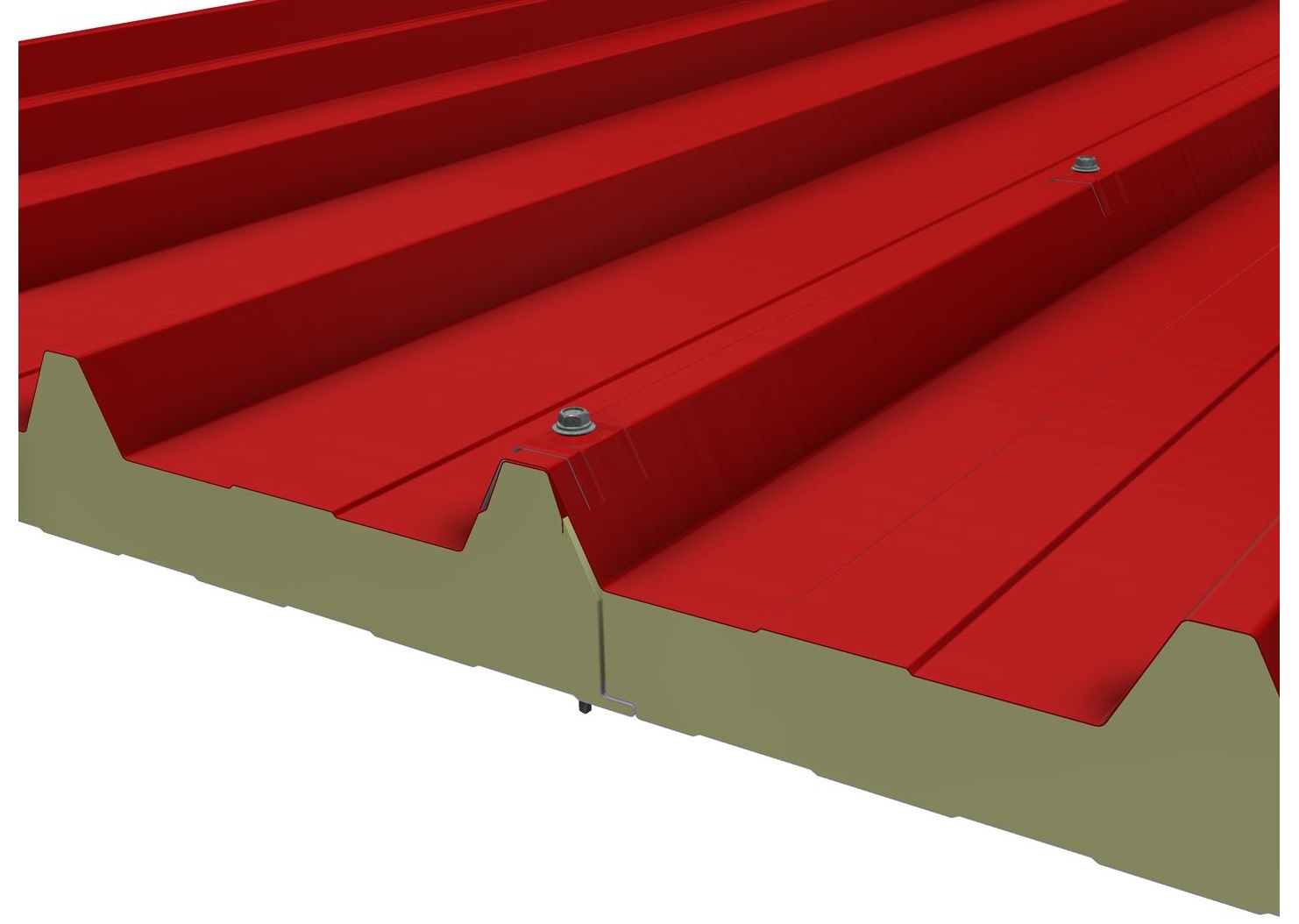

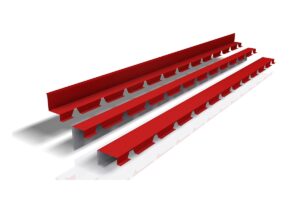

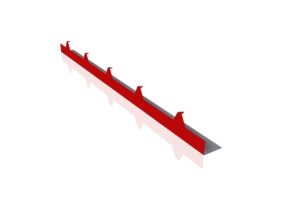

Outer Sheet

External metal sheets of trapezoidal cross-section 42/250 (five vertices) or trapezoidal cross-section 42/500 (three vertices), with a slight groove (Box) between the vertices. Usually the sheets used are unprinted, but there is the possibility of embossing.

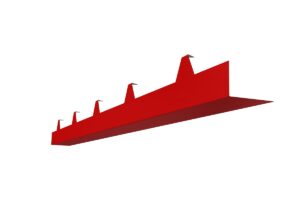

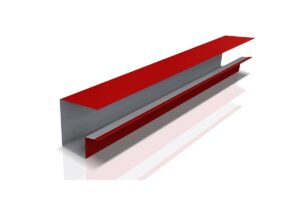

Inner Sheet

Internal metal sheets with no flat configuration (Flat) or with light configuration Box 100 groove (50-50), mini Box 51 groove (25.5-25.5), Box 150 groove (75-75) and sagre impression ( Embossed). It is possible to produce panels where the inner lamina can be replaced with a flat polyester sheet up to 1mm thick, for use in constructions where the environment is extremely corrosive.

Please ask us about available coatings (Polyester, Plastisol, PVDF, Food Safe, Non-Toxic and Anti-mould) and available colors (RAL1014 to RAL 9010).